What You Need To Know About MMA Flooring

30 Jun 2025

- Fully cures within 60 minutes (even at temperatures as low as -30°C), minimising downtime.

- Forms a strong, seamless surface that withstands heavy traffic, chemicals and wear.

- New layers bond chemically to existing surfaces, allowing fast repairs without full removal.

- Non-porous and easy to clean, ideal for food, healthcare and retail environments.

- Available in various colours, textures and anti-slip options to suit design and safety needs.

MMA flooring is a fast-curing, durable solution ideal for high-traffic or time-sensitive spaces such as hospitals, supermarkets, and cold storage areas. We’ve compiled the following Q&A to help you understand why MMA flooring stands out for industrial and commercial use.

1. What is MMA flooring?

MMA (Methyl Methacrylate) flooring is a type of resin flooring system that forms a solid, seamless surface when combined with hardeners and other components. It is commonly used in industries or environments where minimal downtime is critical. The Flowfast product range is an example of MMA-type flooring.

2. How fast does MMA flooring cure, and why is this important?

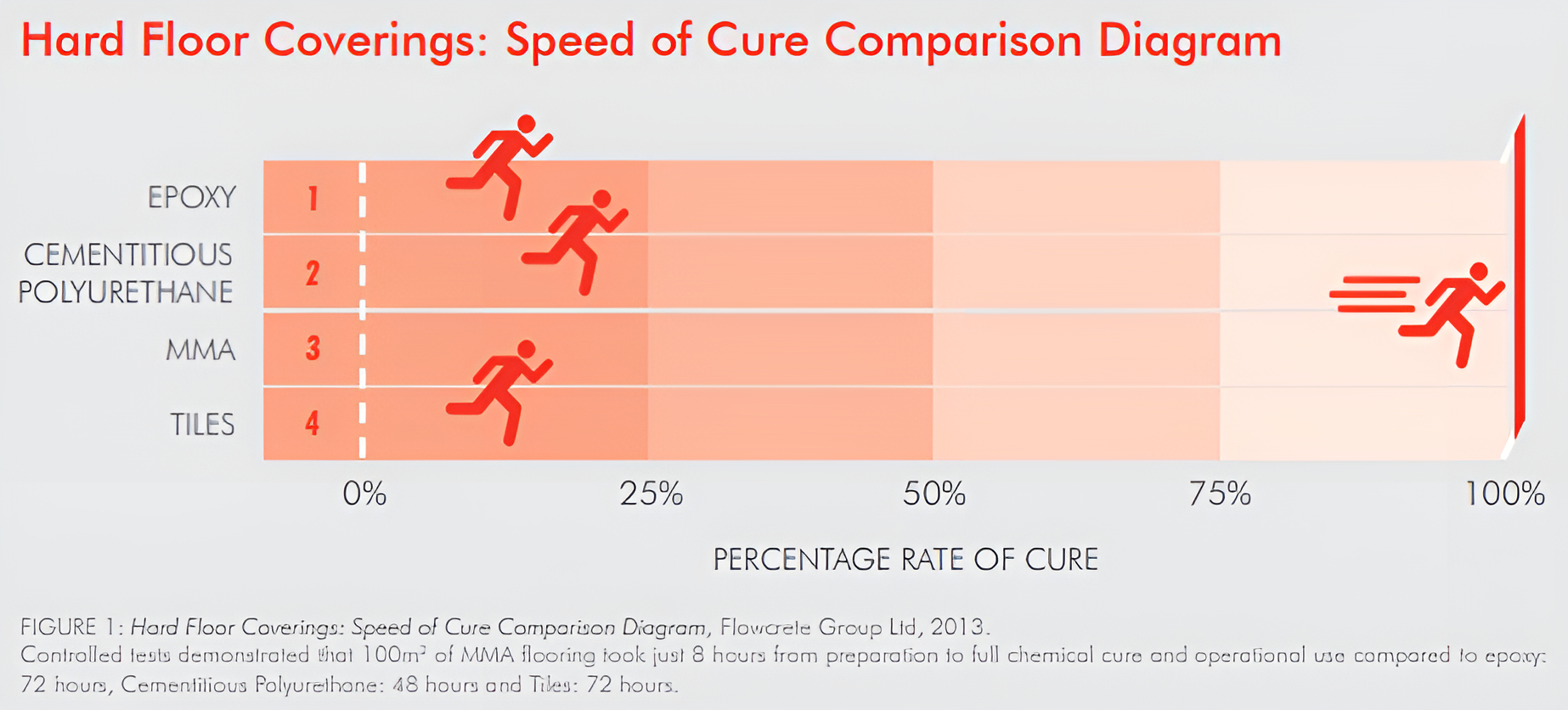

MMA systems can achieve full mechanical and chemical cure within 60 minutes, even in low temperatures. This rapid cure time allows operations to resume almost immediately, reducing downtime for facilities such as supermarkets, hospitals and airports, where lost time equates to lost revenue or operational inefficiencies.

3. What temperature range can I install MMA flooring in?

One of MMA’s key advantages is its ability to cure in temperatures as low as -30°C. This makes it ideal for unheated construction sites or supermarket areas (not for customers) such as cold stores, coolers and blast freezers without the need for any costly temperature control.

4. How is MMA flooring applied?

Unlike labour-intensive and trowel-applied resin systems, MMA flooring can be flow- applied, allowing large areas to be installed more quickly while delivering a quality finish, free from trowel marks.

5. Can MMA flooring be applied over existing surfaces, and can it be repaired or upgraded without full replacement?

Yes. MMA flooring bonds well to various substrates such as concrete, tiles, metal and wood using selected primers that are specifically formulated to ensure optimal adhesion with adequate substrate preparation. It also allows new layers to chemically fuse with existing ones, enabling quick repairs or upgrades without full removal.

6. Should I be concerned about odour during MMA flooring installation?

MMA emits a distinctive odour during application due to volatile monomers. While the smell is non-toxic and dissipates quickly after curing, proper ventilation and odour management strategies (e.g. industrial air purifiers or extractor fans) should be used during installation to minimise disruption.

7. Is MMA flooring environmentally sustainable?

Yes. Modern MMA formulations are low in VOCs, cure quickly to reduce emissions, and are cold applied to save energy. With long lifespans, easy refurbishment and ongoing innovations such as low-odour versions, MMA is becoming a more sustainable flooring choice.

8. What design options are available for MMA floors?

MMA flooring is available in a wide range of colours and finishes. Decorative options such as coloured, glitter or metallic flakes and quartz beads can be added. It can also be customised with patterns or brand-specific colour schemes.

9. I'm managing a supermarket. Do you offer slip-resistant MMA flooring suitable for both staff and customer areas that I can recommend to management?

Yes. MMA flooring is available in both smooth and non-slip finishes. Anti-slip quartz aggregates can be added to create textured surfaces, improving safety in wet or high-traffic areas like production floors and supermarkets. Additionally, it also provides aesthetic finishes if coloured quartz is selected.

10. How long does MMA flooring last?

MMA floors are highly durable, where it creates a strong chemical and mechanical bond with the substrate and each layers. With proper care, these floors can last over 15 years.

ENDS

Enjoy this post? Click below to share it with your network:

Press Contact

For Flowcrete Asia’s contact details please visit www.flowcreteasia.com/contact-us or email [email protected].

Notes to Editors

Flowcrete is a world leader in the manufacture of seamless industrial and commercial resin floor, wall and coving solutions as well as other specialist coating technologies. Flowcrete Asia is now part of Tremco Construction Products Group.

Tremco Construction Products Group APAC has served as the benchmark for excellence and quality products since our first entry of our brands into the Asia Pacific market in 1984. Our commitment to serving our clients in a variety of areas with innovative and strategic technology products has allowed us to consistently grow for over 30 years. As of 2020, we have established a strong business presence in countries including Australia, Singapore, Malaysia, Indonesia, South Korea, Japan, Taiwan, China, Vietnam, Philippines, Myanmar and Thailand.

Tremco Construction Products Group APAC is a subsidiary of Tremco Inc. based in Cleveland, USA. Our product lines include high-performance silicone and urethane joint sealants, waterproofing membranes, drainage protection, air barrier systems, deck coatings, expansion joints, a full line of passive fire protection systems, and the industry’s only comprehensive line of glazing systems including silicone sealants, tapes, gaskets, and setting blocks. Tremco CPG APAC brands include Tremco, illbruck, Flowcrete, Vandex, Nullifire, Dryvit, Nudura and Euclid Chemical.

For further information please contact [email protected]

Or visit us on the web at www.tremcocpg-asiapacific.com